overview

During the end of my 2023 fall semester, we had to shave salt bricks into with a certain form. As I worked on them, I thought about how and what tool I could design to make manually shaving salt easier. So over the course of two weeks, I designed a prototype of a tool that could shape and sculpt a salt brick easily.

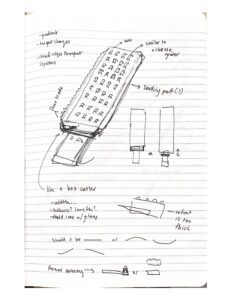

Sketches

Process

To better understand the challenges faced by my classmates and the other tools they used, I made a Google form to gather feedback. After analyzing their responses, I decided to create a tool that will have a better handle, a retractable blade, and subtract more salt with an easier clean-up.

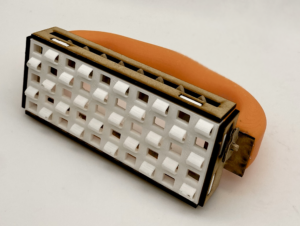

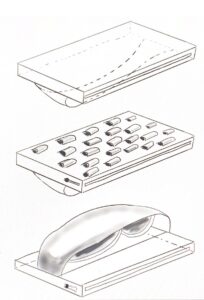

My solution features a blade with holes that allow salt dust to pass through, preventing clogs and improving overall performance. I also incorporated a bidirectional grater that can be pushed both forward and backward, unlike the Stanley foam shavers that only work in one direction. This design allows for more salt to be removed, making the process faster and more effective.

To explore my ideas further, I built over five paper prototypes, which helped me refine the design and understand how the tool would feel and function in practice. Through this iterative process, I realized I needed a more ergonomic handle for better comfort during use. I also decided to add a retractable blade mechanism to subtract larger portions of salt.

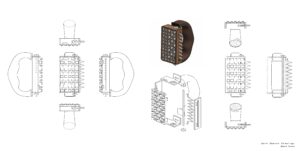

Once I finalized the design, I created 3D models of the parts on Rhino7 for 3D printing and laser cutting. After printing and cutting the components, I assembled them into a working prototype. This process allowed me to test the tool’s functionality, make adjustments, and ultimately develop a product that I believe will be much easier and efficient at shaving salt bricks.

drawings- final product

December 2023